Make / Model Search

Future models - BMW - iX3First Neue Klasse BMW ‘sustainability focused’BMW implements 'clean tech', tighter supply chain controls on second-gen iX3 BEV26 Aug 2025 BMW’s first “sustainability focused” Neue Klasse vehicle, the latest generation iX3 midsize electric SUV, debuts at Munich IAA Mobility show this month featuring an array of technology and manufacturing practices designed to reduce its environmental footprint, bringing the amount of emissions caused by producing each iX3 closer to that of an internal combustion equivalent.

It means that, depending on the energy sources from which it is charged, it can take as little as a year for the iX3’s lifecycle carbon footprint to become lower than that of a petrol or diesel alternative.

The new iX3 simultaneously ushers in a completely different design language for the Bavarian manufacturer and demonstrates the company’s take on implementing a holistic approach to product sustainability across the vehicle’s lifecycle.

BMW says this was demonstrated during product development when extensive measures were brought to bear throughout the supply chain, production and use phases that were explicitly focused on conserving resources and reducing the model’s environmental impact.

It is similar to the methods behind all-electric brand Polestar’s much-publicised ‘life cycle assessment’ for each of its product lines.

As such, the Neue Klasse iX3 marks an important milestone toward achieving BMW's 2030 and 2050 carbon dioxide targets.

The key levers to reduce carbon dioxide emissions in the supply chain are the use of secondary materials and renewable energy, alongside product and process innovations.

BMW claims this combination of measures has led to a reduction of carbon dioxide emissions in the supply chain of 35 per cent during product development.

In a statement, BMW said: “The extensive decarbonisation measures in the supply chain results in an early break-even point: when charged with electricity from the European energy mix, the carbon dioxide footprint of the new BMW iX3 50 xDrive is lower than that of a comparable model with a combustion engine after about 21,500 kilometres (WLTP combined).”

“When charged exclusively with electricity from renewable sources, the BMW iX3 50 xDrive beats the comparable ICE model after only 17,500 kilometres (WLTP combined), allowing customers to potentially achieve COâ benefits in as little as one year.”

Additional to tighter supply chain controls, the new iX3 uses new-generation battery cells in the iX3 high-voltage storage system that are made of 50 per cent secondary cobalt, lithium, and nickel materials.

Renewable energies power production of the anode and cathode materials, and cell production itself, which BMW says yields a 42 per cent reduction in carbon dioxide emissions per kilowatt hour compared with the previous model.

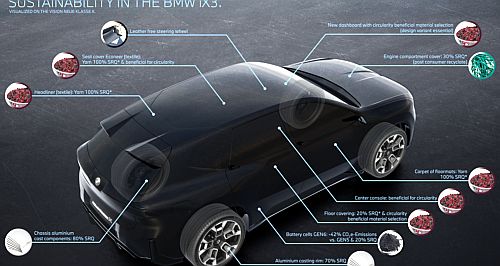

Under its catchphrase “Design for Circularity” other means BMW uses for carbon dioxide and environmental footprint reduction on the new iX3 include the innovative use of secondary materials

Assorted components including the engine compartment cover and the storage compartment under the front hatch are 30 per cent secondary raw material from recycled maritime plastic.

The “post-consumer” plastic material consists of old fishing nets and ropes and BMW’s use of it in Neue-Klasse vehicles prevents these materials from potentially being dumped in the ocean.

Similarly, secondary aluminium accounts for 80 per cent of the wheel carriers and swivel bearings as well as 70 per cent of the cast aluminium wheels.

The Econeer seat cover, available in the iX3 Essential trim level utilises a fabric, adhesive and fleece all made from PET (polyethylene terephthalate) a so-called mono-material that increases recyclability with the textile yarn used consisting entirely of recycled PET.

Other components made under the ‘Design for Circularity’ approach include the centre console, instrument panel and interior floor trim.

Secondary materials account for one third of all material used in the new BMW iX3 50 xDrive.

The vehicle’s EfficientDynamics system consistently identifies and activates efficiency-boosting potential in vehicle subsystems to help the iX3’s overall energy consumption drop by 20 per cent over that of the previous model (on the WLTP combined cycle).

However, much of the energy consumption improvement has been achieved primarily via optimised aerodynamics, reduced rolling resistance and lower onboard power consumption as well as the drivetrain’s efficiency.

The new iX3 will be produced at BMW Group’s sustainability-centric Debrecen plant in Hungary and is scheduled to arrive Down Under in 2026 after a production start late this year.  Read more15th of August 2025  BMW to rival Mercedes-Benz G-ClassReport suggests BMW will chase Mercedes-Benz G-Class buyers with X5-based off-roader24th of July 2025  BMW launches X5 Shadow EditionUnique specification and styling offered in BMW X5 Shadow Edition, priced from $146,9009th of July 2025  BMW launches 3 Series 50 Jahre Edition3 Series’ golden anniversary celebrated with launch of M340i xDrive based 50 Jahre EditionAll future models Alfa Romeo Alfa Romeo Abarth Abarth Audi Audi Aston Martin Aston Martin BMW BMW Bentley Bentley Chrysler Chrysler Chevrolet Chevrolet Dodge Dodge Citroen Citroen Ferrari Ferrari DS DS Ford Ford Fiat Fiat FPV FPV Foton Foton Haval Haval Great Wall Great Wall Honda Honda Holden Holden Hyundai Hyundai HSV HSV Isuzu Isuzu Infiniti Infiniti Jaguar Jaguar Iveco Iveco Kia Kia Jeep Jeep Land Rover Land Rover Lamborghini Lamborghini Maserati Maserati Lexus Lexus McLaren McLaren Mazda Mazda Mercedes-Benz Mercedes-Benz Mitsubishi Mitsubishi Mini Mini Opel Opel Nissan Nissan Porsche Porsche Peugeot Peugeot Ram Ram Proton Proton Rolls-Royce Rolls-Royce Renault Renault Skoda Skoda Saab Saab SsangYong SsangYong Smart Smart Suzuki Suzuki Subaru Subaru Toyota Toyota Tesla Tesla Volvo VolvoMotor industry news |

Click to shareBMW modelsResearch BMW All future models Alfa Romeo Alfa Romeo Abarth Abarth Audi Audi Aston Martin Aston Martin BMW BMW Bentley Bentley Chrysler Chrysler Chevrolet Chevrolet Dodge Dodge Citroen Citroen Ferrari Ferrari DS DS Ford Ford Fiat Fiat FPV FPV Foton Foton Haval Haval Great Wall Great Wall Honda Honda Holden Holden Hyundai Hyundai HSV HSV Isuzu Isuzu Infiniti Infiniti Jaguar Jaguar Iveco Iveco Kia Kia Jeep Jeep Land Rover Land Rover Lamborghini Lamborghini Maserati Maserati Lexus Lexus McLaren McLaren Mazda Mazda Mercedes-Benz Mercedes-Benz Mitsubishi Mitsubishi Mini Mini Opel Opel Nissan Nissan Porsche Porsche Peugeot Peugeot Ram Ram Proton Proton Rolls-Royce Rolls-Royce Renault Renault Skoda Skoda Saab Saab SsangYong SsangYong Smart Smart Suzuki Suzuki Subaru Subaru Toyota Toyota Tesla Tesla Volvo VolvoMotor industry news |

Facebook Twitter Instagram